Graphite Molds Expert. E-mail us info@hifounder.com

Research & Development Center

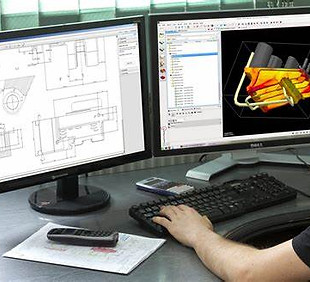

Hifounder Graphite has one of the North Chinese strongest expert and engineering teams in Graphite molds products. The R&D center maintains a full staff of over 10 engineers and CAD technicians, ranging from mold design and fabrication to production and quality control. With deep roots in engineering innovation, Hifounder Graphite's principals provide us with expertise and experience in the advancement of design and production.

Key Point

QC Responsibility

Our QC in manufacturing highlights the importance of thorough examination and testing of the product quality to find defects.

the Raw Material

1.All of the raw materials are sourced from the certified steel works directly with the qualified test report.

2.The raw material samples are selected randomly from bulk goods before the bulk production and then submit to make microscopy and hardness tests to analyze their structure, composition etc., and match with the standard to make sure the raw material was qualified.

Inspection for Dimension

The first batch of bulk products are checked on the worktable according the technical drawing. During the production, the special inspection tools are applied to control the Dimension.

Mechanical testing

Before the delivery, we need the report to reassurance and certify that our precast concrete accessories were qualified for an intended use, such as lifting, connection or meets the customer’s specifications.Mechanical testing uses impact, tensile and hardness testing to safety of our precast concrete accessories.The testing is an integral process to test our metal or alloy products performs under exacting conditions and whether it complies with the qualified products standards.